MCR Safety D3O Impact Gloves set the standard for advanced impact and vibration hand protection. Engineered with advanced D3O material, these work gloves provide exceptional impact resistance, durability, and flexibility for demanding work environments. Whether you’re in construction, manufacturing, or heavy equipment operation, these gloves are built to handle the toughest tasks with ease.

What Are MCR Safety D3O Impact Gloves?

Firstly, MCR Safety D3O Impact Gloves incorporate advanced materials and innovative designs to offer superior impact resistance, durability, and flexibility. With features like anti-vibration technology, ANSI cut resistance, and TPR knuckle protection, these gloves provide exceptional performance for demanding tasks. Available in styles such as high-visibility, cold-resistant, heat-resistant, extra grip, puncture-resistant, and touchscreen-compatible, they cater to a variety of industries and job requirements.

MCR Safety ForceFlex Series

Most of all, the ForceFlex series stands out as a premium choice in the MCR Safety D3O Impact Gloves lineup. Designed with extreme conditions in mind, these gloves feature flexible D3O material for unmatched impact resistance and dexterity. Reinforced fingertips and padded palms ensure added durability and comfort during extended use. Also, styles in this series include options for ANSI cut resistance, high visibility, and enhanced grip. This work glove series for the oil and gas industry offers wet, dry, and oily grip. ForceFlex gloves deliver dependable protection without compromising the wearer’s ability to handle tools and equipment with precision.

MCR Safety Predator Multi-Task Gloves

In addition, for versatile hand protection, MCR Predator Multi-Task gloves are a top-tier option. These gloves combine D3O impact protection with additional features like puncture resistance, anti-vibration technology, and TPR knuckle shields. With a focus on flexibility and durability, Predator gloves are ideal for several industries. This includes construction, oil and gas, and heavy equipment operations. Also, the automotive and mechanic industries rely on the comprehensive safety these gloves provide. Cold-resistant and touchscreen-compatible styles provide additional functionality, ensuring workers stay safe and efficient in any condition.

What Is D3O Material?

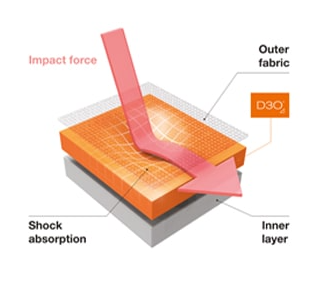

Furthermore, D3O material is a groundbreaking innovation in impact-resistant gloves and other safety gear. Made from a unique polymer blend, it remains soft and flexible during regular use but hardens instantly upon impact to absorb and dissipate energy. This technology protects against hand injuries caused by sudden shocks, impacts, and vibrations. By reducing the strain on muscles and joints, D3O enhances comfort and safety, making it an excellent choice for workers in physically demanding roles.

Why Choose MCR Safety D3O Impact Gloves?

Finally, MCR Safety D3O Impact Gloves offer unmatched protection and versatility. Styles include heat-resistant gloves for handling hot materials, high-visibility options for improved safety in low-light conditions, and touchscreen-compatible designs for seamless device use. Anti-vibration technology reduces fatigue during extended tasks, while ANSI cut resistance and puncture-resistant materials shield against sharp objects and abrasions. Whether you need gloves for heavy construction, mechanical work, or extreme cold environments, MCR Safety has a solution tailored to your needs.

Conclusion

In conclusion, MCR Safety D3O Impact Gloves provide a perfect blend of innovation, durability, and versatility. With advanced D3O technology and a wide range of features, these gloves deliver unmatched protection for professionals in demanding industries. Explore options like the ForceFlex and Predator Multi-Task gloves to find the perfect fit for your job and experience the difference that quality hand protection can make.