Whether you’re working in construction, traffic control, or any other industry where visibility is crucial, wearing ANSI certified reflective safety jackets is an absolute must. In this blog post, we’ll delve into the importance of wearing ANSI-certified reflective safety jackets. And tell you how they keep you warm and can protect you from potential hazards. So don’t compromise your safety – stay safe and stay seen.

Introduction to ANSI and Non-ANSI Reflective Safety Jackets

First of all, reflective safety jackets are essential protective gear for workers who are exposed to hazardous conditions and low visibility environments. These jackets enhance the visibility of workers, ensuring easy identification and lowering the risk of accidents. However, reflective safety jackets vary in quality. Some may offer more protection than others, depending on their compliance with certain standards. And our best-selling brands like Radians, Kishigo, and Pyramex offer a variety of safety jacket styles.

The American National Standards Institute (ANSI) sets one of the most recognized standards for reflective safety jackets in the United States. ANSI has established guidelines for high visibility apparel. This includes reflective safety jackets, to ensure that they meet specific requirements for design, materials, and performance. And reflective safety jackets meet ANSI Type O Class 1, ANSI Type P and R Class 2. And ANSI Type R Class 3 ratings for the job site.

Also, non-ANSI reflective safety jackets do not comply with these strict standards but still provide some level of visibility enhancement. While they may not offer the same level of protection as ANSI-rated styles, they offer enhanced visibility to the wearer. And non-ANSI safety jackets include hi-vis orange and yellow/lime options like the Port Authority SRJ754. This jacket includes silver reflective tape, a water-resistant shell, and a heavyweight fleece lining for extra warmth.

In this section, we will take a closer look at what makes an ANSI-certified reflective safety jacket different from non-ANSI ones.

What is ANSI Certification?

The American National Standards Institute (ANSI) is a private non-profit organization that oversees the development of voluntary consensus standards for a wide range of products and services in various industries. Their mission is to enhance global competitiveness by ensuring that products are safe and reliable. While also protecting consumer health and environment.

For high visibility apparel like reflective safety jackets to receive an ANSI certification, it must undergo rigorous testing and evaluation to meet the requirements set by ANSI/ISEA 107. This standard outlines the design, materials, and performance criteria for high visibility apparel. It also provides guidance on how to properly use and maintain these garments.

There are three classes of high visibility apparel under this standard, with each class offering a different level of protection based on the worker’s job function and work environment.

ANSI Class 1-3

Class 1: Class 1 garments provide the minimum amount of visibility enhancement and are suitable for workers in low-risk environments where traffic is moving at speeds below 25 mph. These include parking lot attendants, delivery truck drivers, or workers in warehouses.

Class 2: Class 2 garments offer more visibility enhancement than Class 1. And they cater to workers who are near roadways with traffic speeds surpassing 25 mph. They are suitable for construction workers, road maintenance crews, and utility workers.

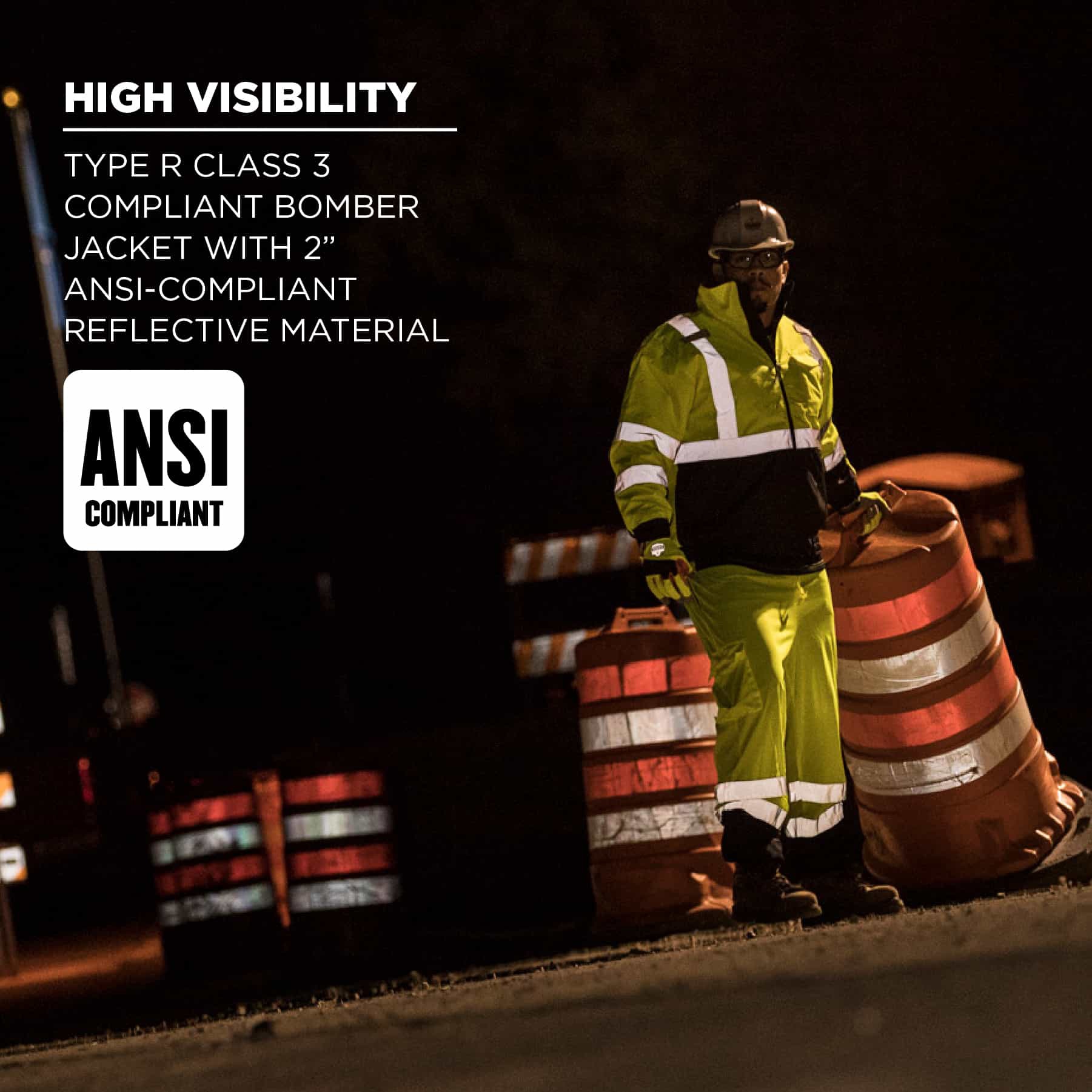

Class 3: Class 3 garments provide the highest level of visibility enhancement. And they design them for workers in high-risk environments facing potential exposure to high vehicular traffic or extreme weather conditions. These include emergency responders, highway construction workers, and tow truck operators.

What is ANSI Certification?

ANSI (American National Standards Institute) is a non-profit organization. It oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. Their goal is to enhance global competitiveness and productivity by ensuring the safety and quality of goods and services.

The ANSI certification is a widely recognized accreditation that signifies compliance with certain standards for safety, performance, and quality. Various industries such as construction, manufacturing, and transportation highly value this certification. And many more where workers are exposed to hazardous environments.

For safety jackets specifically, ANSI has developed specific standards known as the ANSI/ISEA 107-2015 standard for high visibility apparel. This standard outlines the requirements for materials used in making reflective safety jackets including color contrast, luminosity levels of reflective tape or fabric strips, design requirements for background material color and placket width. This ensures that workers wearing these jackets will be easily visible even in low light conditions. Or in adverse weather conditions such as fog or rain.

The Three ANSI Classes

There are three classes of ANSI-certified reflective safety jackets – Class 1, Class 2, and Class 3. Each class has its own set of specifications based on the level of risk associated with the job task being performed.

Class 1: These are for workers requiring minimum visibility protection because of their low-risk work tasks. Examples include parking lot attendants or delivery drivers. These jackets must have a minimum amount of retroreflective material on both front and back. At least 155 square inches of reflective material. And our ANSI Type O Class 1 safety jackets include the Kishigo B300 series. These enhanced visibility jackets come in black, royal blue, and red colors.

Class 2: These are designed for workers who need intermediate visibility protection due to their higher-risk work tasks. Or working in poor weather conditions. Examples include crossing guards, airport ground crew, and railway workers. These jackets must have a minimum of 201 square inches of reflective material and must also have reflective material on the sleeves. Select from options like the ERB Delta Plus W144, ERB by Delta Plus W651, and the Reflective Apparel 407GTLB.

ANSI Classes Continued

Class 3: These are designed for workers who need maximum visibility protection due to their high-risk work tasks or working in very dark conditions. Examples include emergency responders, road construction workers, and utility workers. These jackets must have a minimum of 310 square inches of reflective material with retroreflective material on the sleeves. And popular ANSI Class 3 safety jackets include the Radians SJ11QB-3ZGS, MCR Safety VBBQCL3L, and the Pyramex RJ3110 jackets.

To obtain ANSI certification, safety jackets must undergo rigorous testing by an independent third-party laboratory to ensure they meet the required standards. Once certified, the jacket will bear the ANSI certification label indicating its classification level (Class 1, 2, or 3) and any other relevant information such as flame resistance or waterproofing.

Benefits of Wearing an ANSI-Certified Reflective Safety Jacket

Wearing an ANSI-certified reflective safety jacket on the job is not only a smart choice, but it also comes with numerous benefits. These jackets are specifically designed to provide high visibility and protection for workers in hazardous environments or low-light conditions. Here are some of the key benefits of wearing an ANSI-certified reflective safety jacket:

1. Enhanced Visibility:

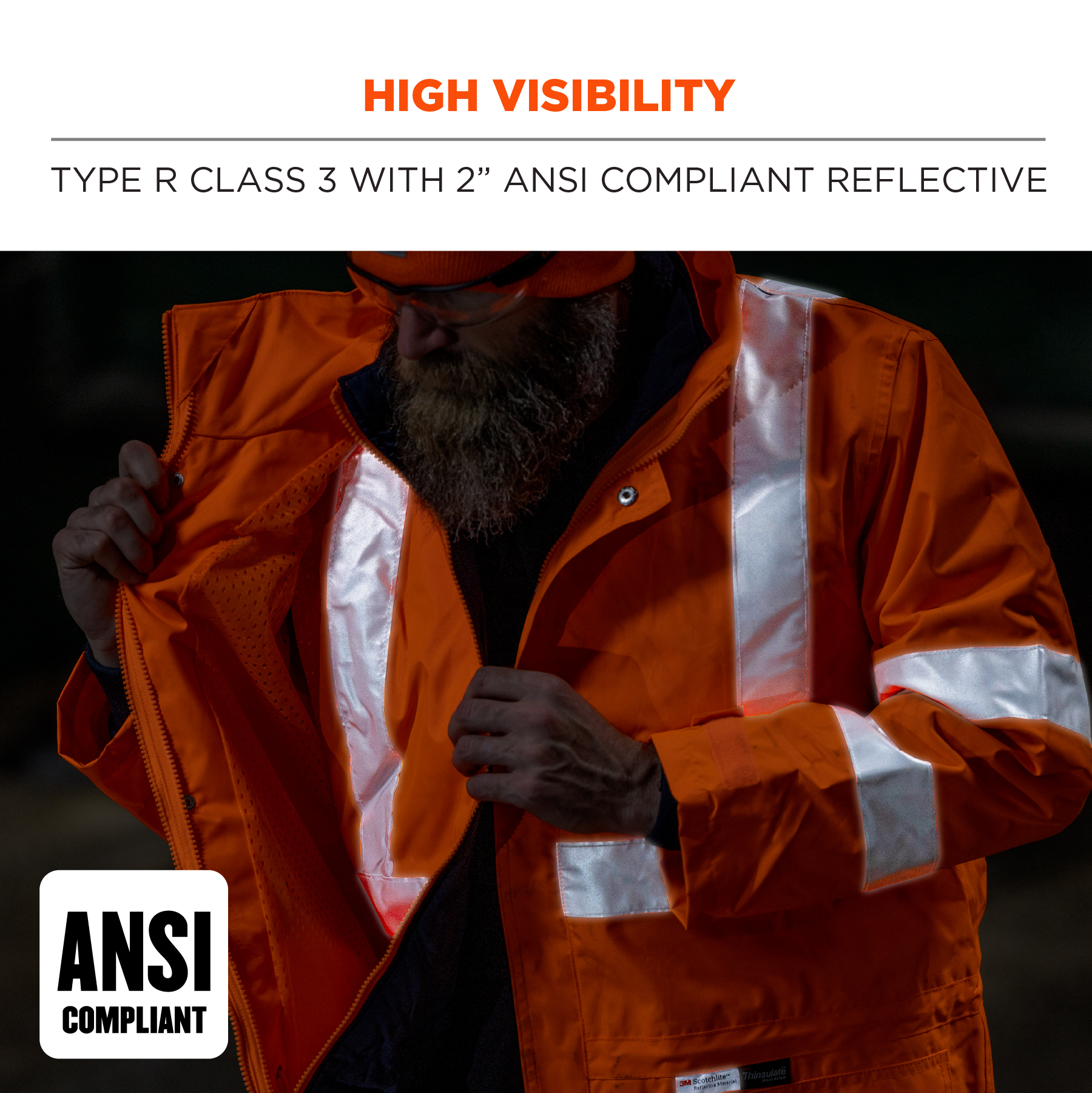

The main purpose of an ANSI-certified reflective safety jacket is to increase visibility, especially in low light situations. These jackets have fluorescent colors such as neon yellow, orange or lime green which make them highly visible during the day. In addition, they also feature retroreflective tape that reflects light back to its source, making it easier for others to see you even in poor lighting conditions.

2. Increased Safety:

Consequently, with enhanced visibility comes increased safety. In high-risk environments like construction sites, road work zones, or warehouses with heavy machinery, visibility is crucial. And this includes your co-workers and other individuals nearby. Wearing an ANSI-certified reflective safety jacket ensures that you are easily spotted by others. In addition, this reduces the risk of accidents and potential injuries.

3. Meets Industry Standards:

Most notably, the American National Standards Institute (ANSI) establishes standards for high-visibility clothing for workers in dangerous settings where moving vehicles or other hazards might expose them. The ANSI certification guarantees that the jacket meets specific performance requirements such as color and reflectivity levels which ensure maximum visibility and protection for the wearer.

More Benefits

4. Versatility:

Also, these hi-vis safety jackets come in a range of styles and designs, making them suitable for a variety of industries and job roles. From traditional construction workers and road crews to warehouse employees and emergency responders, anyone working in potentially hazardous conditions can benefit from wearing an ANSI-certified reflective safety jacket. And add your custom name or logo with our professional embroidery to promote your brand and business. Our custom logo reflective safety jacket also includes affordable vinyl heat press options.

5. Comfort:

Most ANSI-certified reflective safety jackets are made with lightweight materials like cotton and polyester. These materials provide comfort and warmth without compromising on protection. And for the coldest weather conditions, look for options like bomber jackets and parkas. These jackets have features like quilted liners, hoods, and thermal insulation. Also, select from a range of sizes and styles for men and women.

6. Durability:

Furthermore, these jackets are built to withstand tough working conditions. And this means that manufacturers use durable materials in their construction to resist wear and tear. They include options with water-resistant, wind-resistant and have reinforced stitching to ensure they maintain their functionality even after extended use. And select from a variety of durable jacket styles like hi-vis reflective rain jackets, bomber jackets, and parkas.

Differences between ANSI-Certified and Non-ANSI Reflective Safety Jackets

Also, when it comes to ensuring safety on the job, reflective safety jackets are an essential piece of protective gear. Designers create these jackets to enhance worker visibility in low light or dark conditions, thus decreasing the chance of accidents and injuries. However, not all reflective safety jackets are created equal. Some may be ANSI-certified while others are not. In this section, we will discuss the key differences between ANSI-certified and non-ANSI reflective safety jackets.

1. Certification Standards: The American National Standards Institute (ANSI) is a non-profit organization that sets standards for various industries, including workplace safety. Regarding reflective safety apparel, ANSI establishes specific requirements a jacket must meet to receive certification for safe job use. Non-ANSI jackets do not meet these standards and may not provide the same level of protection.

2. Reflective Material Quality: The quality of reflective material used distinguishes between ANSI-certified jackets and non-ANSI jackets. ANSI-certified jackets must have highly reflective material that meets certain brightness and durability standards. This allows for maximum visibility even in low light conditions and ensures that the jacket will remain effective over time. And this includes ANSI class 2 and 3 jackets from the Ergodyne GloWear series.

3. Background Material Requirements: In addition to high-quality reflective material, ANSI also requires certified jackets to have a specific amount of background material in fluorescent colors such as yellow, orange, or green. This creates contrast with the reflectivity and makes workers stand out even more in low-light situations.

Factors to Consider When Choosing a Reflective Safety Jacket

When it comes to choosing a reflective safety jacket, there are several important factors to consider in order ensuring you are getting the best protection on the job. Here are some key considerations to keep in mind when selecting a reflective safety jacket:

1. ANSI Certification: The first and most crucial factor to consider is whether the safety jacket is ANSI-certified. ANSI (American National Standards Institute) sets standards for reflective materials used in high-visibility apparel, ensuring that they meet certain requirements for visibility and durability. Look for jackets with an “ANSI/ISEA 107” label, which indicates compliance with these standards.

2. Type of Reflective Material: Reflective safety jackets use different types of materials for their reflective strips or panels. The most common options are 3M Scotchlite reflective material, phosphorescent tape, and microprismatic tape. Microprismatic tapes provide both high reflectivity and durability, making them a popular choice.

3. Color of Background Material: Another important aspect to consider is the color of the background material on the jacket itself. The most effective contrast for visibility is between yellow or lime green background material and silver or white reflective strips. These colors also tend to stand out better against different backgrounds such as construction sites or roads.

Conclusion

In conclusion, in this fast-paced and demanding world, it’s easy to overlook safety precautions in pursuit of productivity. However, when it comes to working in hazardous environments or during low visibility hours, making sure your safety is a top priority is crucial. This is where ANSI-certified reflective safety jackets come into play. One of the most significant benefits of wearing an ANSI-certified reflective safety jacket is its ability to prevent accidents. By increasing visibility, these jackets reduce the chances of workers being hit by moving vehicles or equipment. This not only protects individuals and keeps you warm, but also maintains a safe work environment for everyone on site.