In the vibrant world of garment customization, vinyl heat press stands out as a popular, versatile, and effective technique that brings designs to life on various textiles. This method, beloved for its durability and precision, allows individuals and businesses to create high-quality, personalized apparel and accessories. Whether you’re a budding entrepreneur, a creative enthusiast, or someone looking to add a personal touch to your wardrobe, understanding the vinyl heat press process can open up a world of possibilities.

The Basics of Vinyl Heat Press

First of all, vinyl heat press involves cutting out designs from a special heat-transfer vinyl material. Then apply them to the fabric using a heat press machine. This machine combines heat and pressure to ensure the design adheres firmly to the material. The precision of the cut, the quality of the vinyl, and the consistent application of heat and pressure are crucial for a flawless finish. Thus the result is a smooth, professional-looking design that is firmly attached to the fabric and can withstand washing and wear.

Advantages of Vinyl Heat Press Customization

Durability

While vinyl heat press, or cad cut, offers several benefits, durability is a standout. One of the most significant benefits of vinyl heat press customization is the longevity of the design. When correctly applied, the vinyl can last as long as the garment itself, maintaining its color and vibrancy through countless washes. Plus, this type of customization works well on high-visibility safety jackets. Add your vinyl logo to hi-viz safety jackets from brands like Radians, MCR Safety, Pyramex, and Ergodyne.

Also, the quality of the vinyl material, combined with the precise heat and pressure application, ensures that logos adhere strongly to the fabric, offering resistance to the rigors of daily wear and regular laundering. This resilience makes vinyl heat press logos an excellent option for everything from corporate uniforms to sports team gear, ensuring that the branding or design remains intact and visually appealing for the long haul.

Versatility

Likewise, this method is suitable for a wide range of fabrics and items, from t-shirts and hoodies to hats and bags. It’s also perfect for creating different designs including text, logos, and graphic motifs, offering endless possibilities for personalization. However, some logos may be too complex for vinyl heat transfers. Our low-cost printing, starting at 99 cents per print, is an option for most other customization jobs.

Precision and Quality

In addition, vinyl heat press provides a clean, detailed, and professional appearance. The edges are crisp, and the colors are vibrant, ensuring that the final product is of high quality. Vinyl heat transfers have a shorter preparation time, but the process of pressing each garment is slow. For each item, the text must be cut using a plotter machine, weeded by hand to remove excess vinyl, and heat pressed. Therefore, this means that the time needed to press five garments versus ten is almost doubled.

How does the vinyl heat transfer process work?

Furthermore, the vinyl heat transfer process works by taking a piece of vinyl material, placing it over top of the apparel, and pressing both together using a heat press. Before the vinyl can be placed, the text you specified in your order must be cut using a cutting machine. Then, once the machine has cut the vinyl, it is then taken over to the heat press where your garment and text are bonded together at 300 degrees.

Cost-Effectiveness

While for small to medium-sized runs, vinyl heat pressing is incredibly cost-effective. It requires minimal setup making it ideal for smaller custom orders. We offer vinyl heat press logos with a minimum of 25 garments per order. Also, our pricing for vinyl heat transfers is not tiered and is the same price no matter how many you order. The pricing for vinyl heat transfers per location can be viewed below:

| Quantity | Price | |

| 1 Color | 25 or More | $6.99 |

| Silver Reflective | 25 or More | $9.99 |

Creative Possibilities and Applications

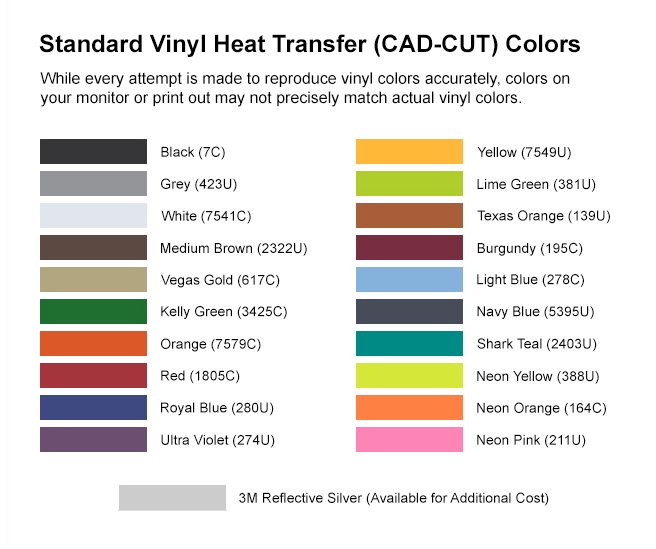

At the same time, vinyl customization isn’t just for safety gear; it’s perfect for small custom orders of blank apparel and casual wear for sports teams, schools, and for personal use. Also, it’s a fantastic way to create custom merchandise, personalized gifts or uniforms. Select from dozens of popular blank apparel brands like Port Authority, Sport-Tek, Hanes, Gildan, Port & Company, and District. Also, we offer 20 different vinyl colors for your text or logo including silver reflective.

Our Standard Vinyl Heat Transfer (CAD-CUT) Color Chart:

Tips for Perfect Customization

Follow Care Instructions

Finally, to maintain the longevity of the vinyl on most casual wear apparel, follow proper care instructions. This often involves washing inside out, avoiding bleach, and tumble drying on low.

Conclusion

In conclusion, vinyl heat press customization empowers you to transform your blank apparel and accessories into unique, personalized creations. With its blend of durability, versatility, and high quality, vinyl heat press stands as a testament to the innovative world of personalized apparel and accessories. Elevate your blank apparel with our vinyl customization process.