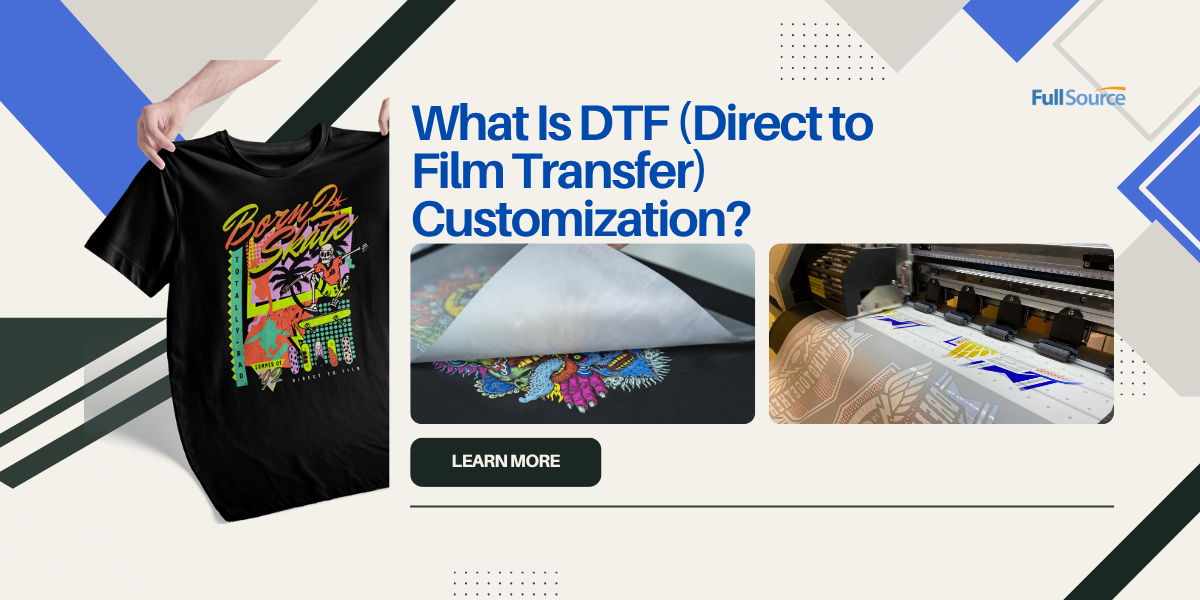

DTF, or Direct to Film transfer, is changing how people add high-quality graphics to apparel. This printing method offers a flexible, efficient way to customize garments, especially workwear, blank apparel, and accessories. Unlike traditional methods that limit material compatibility, DTF works on cotton, polyester, blends, and even synthetic fabrics.

How the DTF Process Works

First, designers print the artwork onto a special PET film using DTF printers and water-based pigment inks. These printers create a white base layer followed by vivid color layers for full detail and clarity. After printing, a hot-melt adhesive powder coats the printed area on the film.

Next, the adhesive-coated film moves through a curing process. A curing oven or heat press melts the adhesive and prepares it for transfer. Once cured, the film is aligned with the fabric and pressed using heat and pressure. After cooling, the film peels away cleanly, leaving a durable and vibrant design.

Why DTF Stands Out from Other Methods

Additionally, while methods like DTG (Direct to Garment) work mainly on cotton, DTF handles a wider range of fabrics with ease. It produces detailed, colorful prints with excellent stretch, making it ideal for everyday use and rugged work environments. Also, the direct to film transfer process allows us to replicate logos with dozens of vivid colors.

Benefits of DTF Printing:

- Works on a wide range of fabrics (cotton, polyester, blends, and more)

- No pre-treatment needed (unlike DTG for cotton)

- Vivid colors and fine detail

- Durable and flexible prints

- Cost-effective

Screen Printing vs. Direct to Film Logos

Likewise, compared to traditional screen printing, Direct to Film (DTF) logos offer greater versatility, sharper detail, and lower setup costs. This includes short runs or complex, multi-color designs. Screen printing requires separate screens for each color, making it time-consuming and less cost-effective for small orders. In contrast, DTF prints full-color images in a single pass without the need for screens, allowing for faster turnaround and finer detail. While screen printing remains ideal for high-volume, single-color jobs, DTF excels in flexibility, fabric compatibility, and producing vibrant, high-resolution logos on demand.

Affordable, High-Quality Logos for Blank Apparel

Moreover, DTF offers a cost-effective way to apply logos to blank apparel. Whether you need safety vests, t-shirts, hats, or bags, DTF includes no setup fees and delivers impressive print quality. Also, we offer PMS color matching for logos for an additional fee. Our low minimum quantities and tiered pricing make this method perfect for branding uniforms, promotional giveaways, or custom accessories.

Ideal for Workwear and Safety Gear

Furthermore, the DTF process works well on most safety apparel and gear. Its ability to bond with hi-vis polyester and structured surfaces means you can customize safety vests, jackets, shirts, and more without compromising performance. The transfers withstand daily wear, repeated washing, and exposure to tough conditions.

Final Thoughts

In conclusion, DTF combines durability, flexibility, and affordability in one printing method. It gives brands, businesses, and organizations a reliable way to customize a wide range of blank apparel and gear. Whether you’re outfitting a construction crew or promoting a new product, Direct to Film transfer provides a high-quality solution with lasting results.